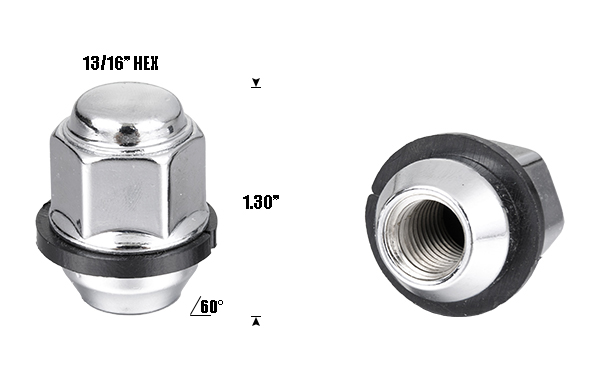

BULGE ACORN WITH GROOVE 1.30’’ Tall 13/16’’ HEX

Product Details

● 13/16’’ HEX

● 1.30’’ Overall Length

● 60 Degree Conical Seat

Multiple thread size available

|

BULGE ACORN |

|

|

Thread Size |

Part# |

|

7/16 |

FN-016-02 |

|

1/2 |

FN-016-04 |

|

12mm 1.25 |

FN-016-06 |

|

12mm 1.50 |

FN-016-07 |

|

14mm 1.50 |

FN-016-09 |

Determine correct lug nut type

To determine the right lug nut for your particular application, you’ll need to consider four different factors: the seat type, thread size, thread pitch and wrenching type.

1.Seat Type

The seat shape is the area where the lug nut is actually in contact with the wheel surface. As mentioned earlier, the most common seat types are flat, spherical, and conical. More specifically, a 60 degree conical lug nut is a very common lug nut design. The conical seat helps to center the wheel when lug nuts are tightened. As a result, you're more likely to end up with well-balanced components than you would with a Mag or Shank seat.

On the other hand, 45 degree conical seats are used more for round track wheels. In fact, you should never use 45 degree lug nuts on an OEM wheel with a 60 degree conical seat.

2.Thread Size

To find out which lug nut threads you need for your vehicle, you need to determine the thread dimensions. To this end, first measure the outside diameter of the vehicle wheel stud thread. It is difficult to obtain accurate measurements using only a tape measure. Instead, a set of digital calipers is used to determine thread dimensions. The most common thread diameters for lug nuts using SAE sizes are 7/16, 1/2, 9/16, and 5/8 inches.

3.Thread Pitch

To determine the pitch, you need to calculate the number of threads along the one-inch portion of the stud. Use a tape measure to cut one inch of line and manually count the number of threads. The most common pitches for SAE-sized lug nuts are 7/16 "-20, 1/2" -20, 9/16 "-18, 5/8" -18, and 5/8 "-11

4.Wrenching Type

Next, we need to determine the wrench type. Hexagon lug nuts are the most common, and both sleeves and wrenches can be easily installed or removed. While this makes it easy for your local mechanic or at a tire shop to remove your wheels, it makes them more vulnerable to theft. If you are worried about theft, we recommend considering purchasing a set of wheel locks.

Both spline drives and hex key nuts require special keys or tools to install and remove them. Spline drive lug nuts are used to match a specific wheel style or to change the overall appearance. Alternatively, for security purposes, you can use a spline drive lug nut for each wheel - commonly referred to as a wheel lock.

However, hexagon key nuts provide a smoother appearance and are commonly used on wheels with small countersunk holes so that the nut fits perfectly. The main advantage of these types of lug nuts is that they do not cause any damage to the surface as they do not come into contact with any outside surface when installed or removed.