Chinese Customized Tire Valves: A Comprehensive Guide

In the ever-evolving automotive industry, the importance of high-quality components cannot be overstated. Among these components, tire valves play a crucial role in ensuring the safety and performance of vehicles. As the demand for specialized automotive parts continues to grow, Chinese customized tire valves have emerged as a popular choice for manufacturers and consumers alike. This article delves into the significance, benefits, and manufacturing processes of Chinese customized tire valves, providing a comprehensive overview for those interested in this essential automotive component.

Understanding Tire Valves

Tire valves are small but vital components that allow for the inflation and deflation of tires. They serve as a seal to prevent air from escaping and are essential for maintaining the correct tire pressure. Proper tire pressure is crucial for vehicle safety, fuel efficiency, and overall performance. A malfunctioning tire valve can lead to air leaks, resulting in under-inflated tires, which can compromise safety and increase fuel consumption.

Types of Tire Valves

1. Schrader Valves: Commonly found in most vehicles, these valves are easy to use and can be inflated with standard air pumps.

2. Presta Valves: Typically used in high-performance bicycles, these valves are narrower and require a specific pump for inflation.

3. Dunlop Valves: Less common, these valves are often found in older bicycles and some motorcycle tires.

Each type of valve has its unique features and applications, but for this article, we will focus on the customization aspect of tire valves, particularly those manufactured in China.

The Rise of Chinese Customized Tire Valves

China has become a global leader in manufacturing, and the automotive parts industry is no exception. The rise of Chinese customized tire valves can be attributed to several factors:

1. Cost-Effectiveness

One of the primary reasons for the popularity of Chinese customized tire valves is their cost-effectiveness. Manufacturers in China can produce high-quality components at a fraction of the cost compared to their counterparts in other countries. This affordability allows businesses to maintain competitive pricing while ensuring quality.

2. Advanced Manufacturing Techniques

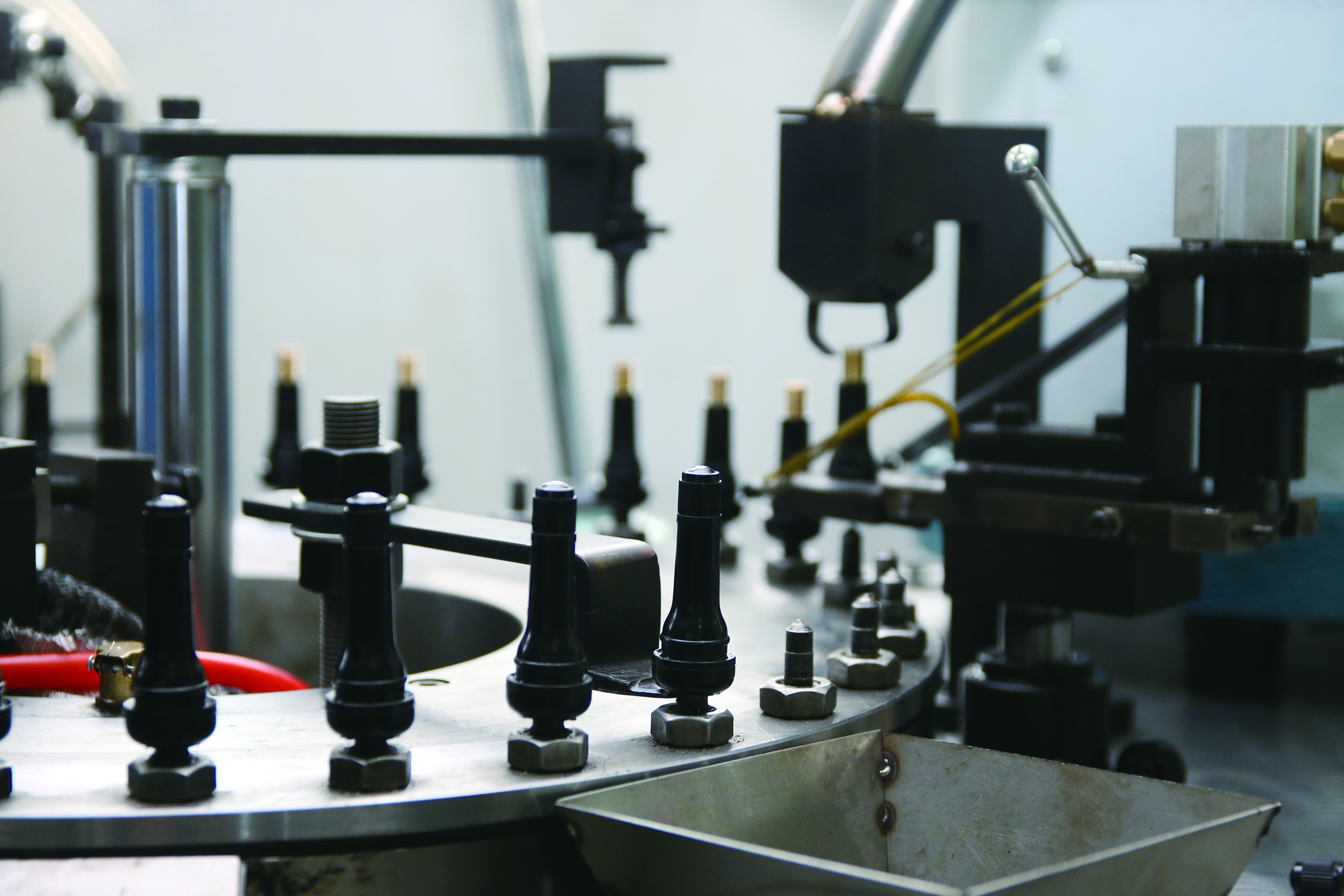

Chinese manufacturers have adopted advanced manufacturing techniques, including automation and precision engineering. These technologies enable the production of tire valves that meet stringent quality standards while allowing for customization to meet specific client requirements.

3. Flexibility in Customization

Chinese manufacturers offer a wide range of customization options for tire valves. This flexibility allows businesses to tailor products to their specific needs, whether it be in terms of size, material, color, or design. Customized tire valves can enhance brand identity and improve product performance, making them an attractive option for manufacturers.

4. Strong Supply Chain

China's robust supply chain infrastructure facilitates the efficient production and distribution of customized tire valves. With access to a wide range of raw materials and components, manufacturers can quickly respond to market demands and deliver products in a timely manner.

Benefits of Chinese Customized Tire Valves

Investing in Chinese customized tire valves offers several advantages:

Environmental Considerations

2. Material Selection

Choosing the right materials is crucial for the performance and durability of tire valves. Common materials include rubber, brass, and plastic. Manufacturers consider factors such as temperature resistance, corrosion resistance, and weight when selecting materials.

3. Production

Once the design and materials are finalized, the production process begins. This may involve injection molding, machining, or other manufacturing techniques. Automation plays a significant role in ensuring precision and efficiency during this stage.

4. Quality Control

Quality control is an essential part of the manufacturing process. Manufacturers conduct rigorous testing to ensure that the customized tire valves meet industry standards and client specifications. This may include pressure testing, leak testing, and visual inspections.

5. Packaging and Distribution

After passing quality control, the tire valves are packaged for distribution. Manufacturers often offer customized packaging options to align with the branding of their clients. Efficient distribution channels ensure that products reach their destination promptly.

The Manufacturing Process of Chinese Customized Tire Valves

1. Enhanced Performance

Customized tire valves can be designed to optimize performance based on specific vehicle requirements. This can lead to improved tire pressure maintenance, reduced air leakage, and enhanced overall vehicle safety.

2. Brand Differentiation

In a competitive market, having unique and customized components can set a brand apart from its competitors. Customized tire valves can feature specific branding elements, colors, or designs that resonate with consumers, enhancing brand recognition and loyalty.

3. Quality Assurance

Many Chinese manufacturers adhere to international quality standards, ensuring that their products are reliable and durable. By choosing a reputable manufacturer, businesses can be confident in the quality of their customized tire valves.

4. Scalability

As businesses grow, their needs may change. Chinese manufacturers can easily scale production to meet increasing demand, making it easier for companies to expand their product offerings without compromising quality.

The manufacturing process of Chinese customized tire valves typically involves several key steps:

1. Design and Prototyping

The first step in creating customized tire valves is the design phase. Manufacturers work closely with clients to understand their specific requirements and create prototypes. Advanced CAD (Computer-Aided Design) software is often used to visualize the design and make necessary adjustments before moving to production.

2. Material Selection

Choosing the right materials is crucial for the performance and durability of tire valves. Common materials include rubber, brass, and plastic. Manufacturers consider factors such as temperature resistance, corrosion resistance, and weight when selecting materials.

3. Production

Once the design and materials are finalized, the production process begins. This may involve injection molding, machining, or other manufacturing techniques. Automation plays a significant role in ensuring precision and efficiency during this stage.

4. Quality Control

Quality control is an essential part of the manufacturing process. Manufacturers conduct rigorous testing to ensure that the customized tire valves meet industry standards and client specifications. This may include pressure testing, leak testing, and visual inspections.

5. Packaging and Distribution

After passing quality control, the tire valves are packaged for distribution. Manufacturers often offer customized packaging options to align with the branding of their clients. Efficient distribution channels ensure that products reach their destination promptly.

Conclusion

Chinese customized tire valves represent a significant advancement in the automotive parts industry. With their cost-effectiveness, advanced manufacturing techniques, and flexibility in customization, these valves are an attractive option for manufacturers looking to enhance their product offerings. The benefits of investing in customized tire valves, including improved performance, brand differentiation, and quality assurance, make them a valuable addition to any automotive business.

As the automotive industry continues to evolve, the demand for high-quality, customized components will only increase. Chinese manufacturers are well-positioned to meet this demand, providing innovative solutions that cater to the unique needs of their clients. Whether you are a manufacturer, supplier, or consumer, understanding the significance of Chinese customized tire valves can help you make informed decisions in this dynamic market.

Post time: Oct-16-2024