Product Details

Jack stands are indispensable tools in the automotive industry, providing crucial support and safety during maintenance and repair tasks. With various styles and designs available, understanding the differences between them is essential for selecting the most suitable option for specific applications. In this article, we will delve into the common types of jack stands and explore their distinct features and functionalities.

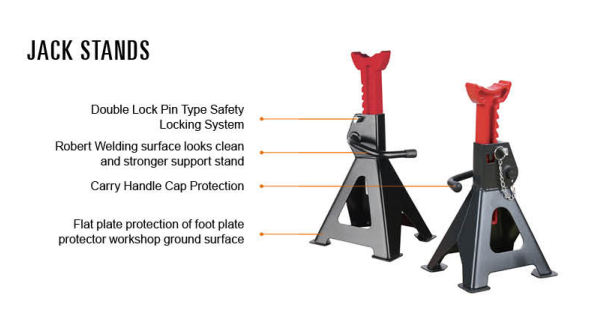

Feature

Traditional Tripod Jack Stands:

1. It typically features a triangular base for stability, with adjustable height settings to accommodate different vehicle heights.

2. It employs a pin mechanism to secure the desired height setting.

3. These stands are favored for their simplicity, durability, and ease of use, making them ideal for general maintenance tasks and tire changes.

Air Bottle Jacks:

1. Many air bottle jacks feature adjustable height settings, allowing users to customize the lifting height to suit their specific requirements.

2. The pneumatic operation of air bottle jacks enables quick and effortless lifting, reducing downtime and increasing productivity.

3. Air bottle jacks offer precise control over the lifting process, allowing operators to raise and lower loads with accuracy and ease.

4. While initially more expensive than manual jacks, air bottle jacks offer long-term cost savings through improved efficiency, reduced labor costs, and increased productivity.

Pin Style Jack Stands:

1. Pin style jack stands employ a pin mechanism to secure the desired height setting.

2. Users insert a pin into pre-drilled holes at various height intervals to lock the stand in place.

3. While not as versatile as ratchet style stands, pin style jack stands are known for their reliability and stability once properly secured.

Air Service Floor Jacks:

1. Built from high-quality materials such as steel or aluminum, air service floor jacks are durable, robust, and capable of handling heavy loads.

2. Many air service floor jacks feature a low-profile design, allowing them to fit under low-clearance vehicles and access hard-to-reach areas.

3. These jacks feature hydraulic mechanisms that generate lifting force, allowing for smooth and precise elevation of heavy loads.

Conclusion

In conclusion, the choice of jack stands depends on factors such as the intended application, load capacity, and user preferences. Whether opting for traditional tripod stands, ratchet style stands, pin style stands, or those with safety locking mechanisms, ensuring proper usage and adherence to safety guidelines is paramount. By understanding the distinct features and differences between various types of jack stands, automotive professionals can make informed decisions to enhance efficiency, productivity, and workplace safety.

Post time: Jun-13-2024