1. Difficulties in Valve Core Assembly Process

In this study, after absorbing the design experience of other automatic assembly systems, the existing semi-automatic assembly system was analyzed, and the mechanical part of the system was completely designed based on the simulation of the valve core assembly process. In the system design plan, we strive to make the processing of the mechanical parts convenient, minimize the cost, make the assembly of parts simple and easy, and make the system have a certain degree of openness and expandability, in order to enhance the reliability and efficiency of the system. , and lay a good foundation for improving the cost performance of the system .

The valve core assembly system is mainly divided into three parts in terms of its mechanical structure design, namely: two assembly parts at the upper left corner of the workbench, three assembly parts at the lower left corner and seven assembly parts at the right side of the workbench part. The technical difficulty of the two-piece assembly lies in how to ensure the circular shape of the sealing ring. During the cutting process, it will be subjected to the axial extrusion force of the blade, so it is easy to deform . Secondly, during the assembly process, when a cored rod is detected on the transfer tooling component, it is necessary to realize the screening and assembly between different components of the door core through vibration. Therefore, each component falls in the corresponding position to become the assembly link. The process difficulty lies in. The above problems are the main reasons for the increase in the defective product rate in the valve core assembly at this stage. Based on this, this paper optimizes the process of valve core assembly, and adds a quality inspection system to improve the qualification rate of valve core assembly.

2. Intelligent Valve Core Assembly Scheme

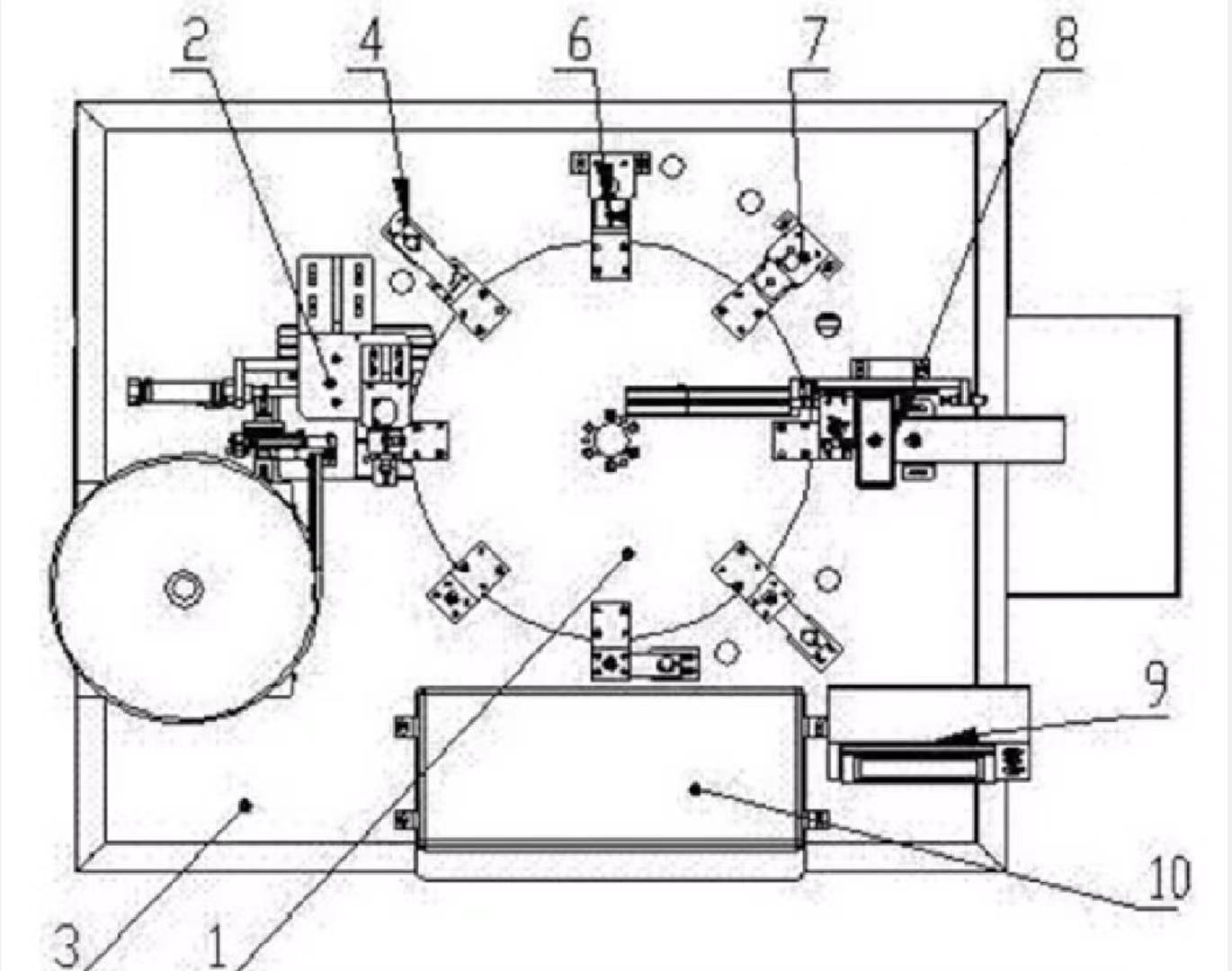

The operation interface and the PLC form a logic control part, and the detection system and the PLC have two-way information flow to collect the status data of the assembly system and output the control signal. As the executive part, the drive system is directly controlled by the PLC output part. Except for the feeding system, which requires manual assistance, other processes in this system have realized intelligent assembly. Good human-computer interaction is achieved through the touch screen. Considering the convenience of operation in the mechanical design, the door core placement box is adjacent to the touch screen. The detection mechanism, the door core top-opening blowing component, the valve core height detection component and the blanking mechanism are respectively arranged around the turntable tooling component, realizing the assembly line production layout of the door core assembly. The detection system mainly completes core rod detection, installation height detection, quality inspection, etc., which not only realizes the automation of material selection and valve core lock, but also ensures the stability and high efficiency of the assembly process. The structure of each unit of the system is shown in Figure 1.

As shown in the figure below, the turntable is the central link of the entire process, and the assembly of the valve core is completed by the drive of the turntable. When the second detection mechanism detects the component to be assembled, it sends a signal to the control system, and the control system coordinates the work of each process unit. First, the vibrating disc shakes the door core out and locks it in the intake valve mouth. The first detection mechanism will directly screen the valve cores that have not been successfully installed as bad materials. Component 6 detects whether the ventilation of the valve core is qualified, and component 7 detects whether the installation height of the valve core meets the standard. Only products that are qualified in the above three links will be captured into the good product box, otherwise they will be treated as defective products.

The intelligent assembly of the valve core is the technical difficulty of the system design. In this design, a three-cylinder design is adopted. The slide cylinder controls the discharge to ensure the uniqueness of the discharge; the second cylinder ensures that the lock rod is aligned with the discharge hole, and then cooperates with the slide cylinder to complete the valve core entering the lock rod, and then The second cylinder continues to push the entire locking mechanism to move, and the suction nozzle will suck the valve when it reaches the bottom of the tooling. Finally, after the third cylinder pushes the locking mechanism into place, the servo motor sends the valve core to the intake valve mouth to complete the assembly of the valve core. This process ensures the accuracy and uniqueness of the longitudinal and lateral movement positions, and provides a good solution to the technical difficulties of door core assembly.

3. Design of Key Components of Valve Core Assembly System

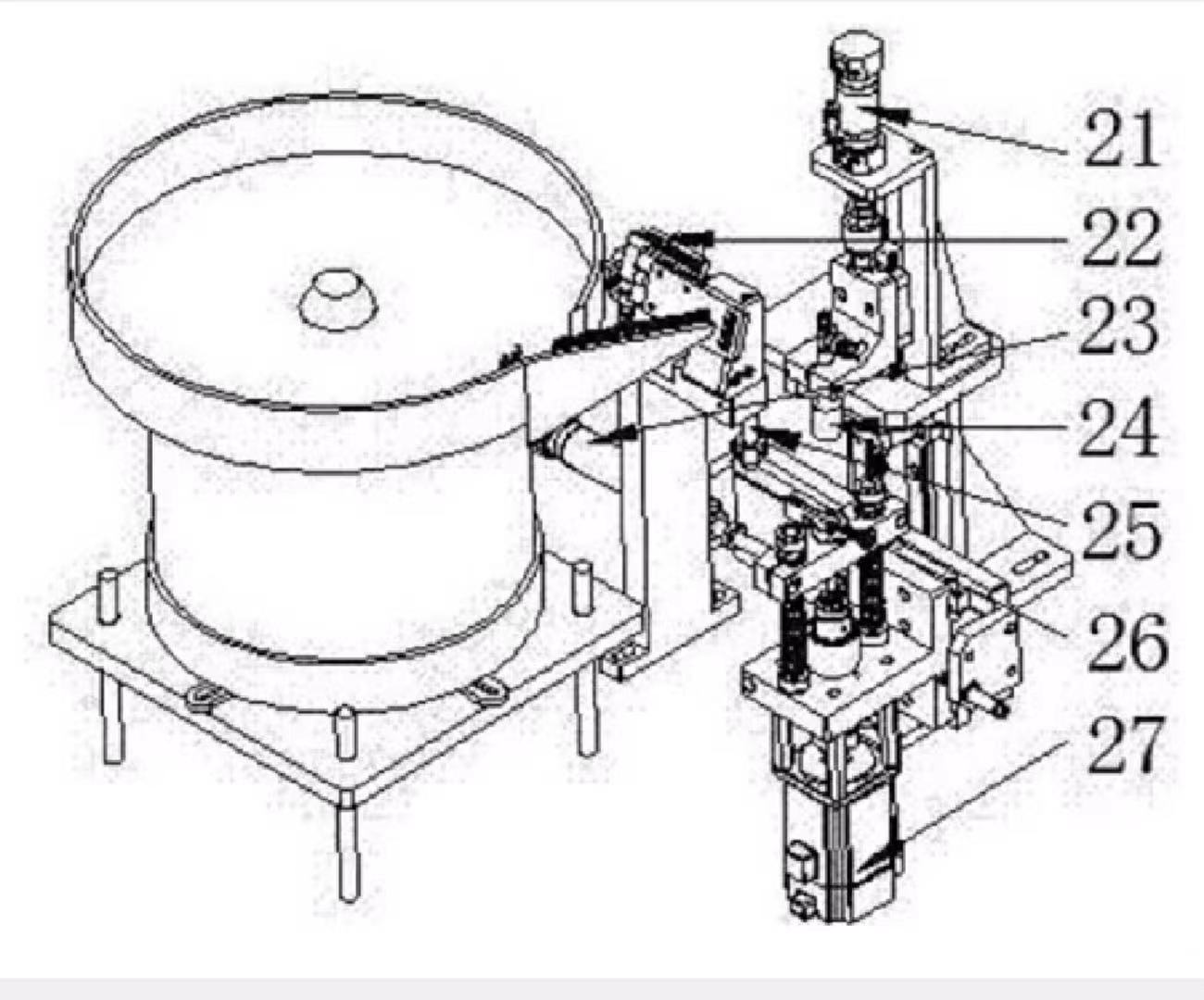

As the key process of installing the valve core on the valve, locking the valve core has very high requirements on the accuracy of the movement position of the valve core, so it needs the coordination of the longitudinal and lateral mechanisms to complete. In the design of this part, it is decomposed into a single action, the discharging action of the valve core, the locking action of the locking lever and the action of loading the valve core on the valve nozzle. Its mechanical structure is shown in Figure 2. As can be seen from Figure 2, the mechanical structure of the valve core assembly is divided into three parts. The three parts work in coordination without affecting each other. When the independent action is completed, the cylinder pushes the mechanism to move to the next assembly position.

In order to ensure the accuracy of the moving position, the comprehensive design of electrical control and mechanical limit is adopted to control the error within 1.4mm. The valve core and the center of the valve nozzle are coaxial, so that the servo motor can push the valve core into the valve nozzle smoothly, otherwise it will cause damage to the parts. Stalling of the mechanical structure or abnormal pulses of electrical signals can cause slight deviations in the assembly work. As a result, after the valve core is assembled, the ventilation performance is not up to standard, and the assembly height is not qualified, which leads to the failure of the product. This factor is fully considered in the system design, air blow detection and height detection are used to sort bad products.

Post time: Sep-09-2022