Importance

Steel wheel weights are an important component used in the automotive industry to balance wheels, ensuring a smoother and safer ride. Made from high-quality steel, these counterweights play a vital role in maintaining vehicle stability and reducing vibrations. In this article, we’ll take a closer look at the importance of steel wheel weights, their benefits, and why they’re better than other alternatives.

Advantages

Firstly, steel wheel weights are widely used in the automotive industry due to their durability and reliability. These Fe wheel weights are designed to withstand harsh weather conditions, extreme temperatures and high speeds, making them suitable for a variety of vehicles including cars, trucks and motorcycles. Even in challenging environments, steel construction ensures counterweights remain intact and functional, lasting longer than other materials.

One of the main benefits of steel wheel weights is their ability to effectively balance the wheel. When wheels are unbalanced, vibration and inconsistencies can result, resulting in an uncomfortable driving experience. Additionally, unbalanced wheels can cause premature tire wear, affecting the overall performance and life of your tires. Steel wheel weights are specially designed to balance any uneven weight distribution, ensuring a smooth and stable ride. By adhering to the rim, these weights require no external clamps, making them easy to install and remove.

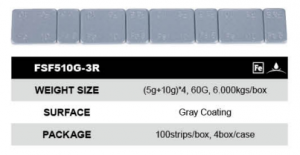

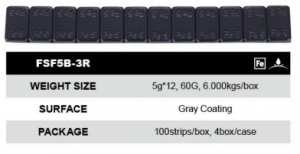

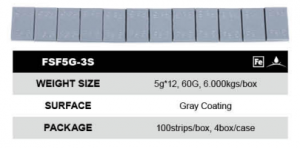

Another significant advantage of steel wheel weights is their versatility. These weights come in a variety of sizes and shapes, allowing manufacturers and mechanics to choose the most suitable option for different wheel types. Whether standard steel rims or aluminum alloy wheels, steel weights are available to suit specific requirements. The ability to customize weights ensures precise balance regardless of wheel size, reducing the risk of further complications such as steering misalignment and suspension issues.

Additionally, the steel wheel weights are designed to be environmentally friendly. Unlike other alternatives such as lead wheel weights, steel weights do not pose any health hazards. Lead has long been used in the automotive industry for wheel balancing, but its toxic properties have raised concerns about its impact on human health and the environment. In response, many countries have enacted regulations restricting the use of lead wheel weights. Steel wheel weights offer a safe and sustainable alternative, allowing manufacturers to comply with these regulations while maintaining high standards of performance.

Finally, steel wheel weights offer cost benefits to manufacturers and vehicle owners. As a durable and long-lasting solution, these weights reduce the need for frequent replacement, saving money in the long run. Additionally, the simple installation and removal process minimizes labor costs, making them a convenient choice for mechanics. Additionally, the versatility of steel bonded wheel weights means manufacturers can stock a variety of sizes and shapes to suit different vehicle models, eliminating the need for multiple products. This not only saves space but also reduces inventory costs.

Conclusion

In conclusion, steel wheel weights are an indispensable component in the automotive industry. Their durability, balance wheel effectiveness, versatility, environmental friendliness and cost-effectiveness set them apart from other alternatives. As the industry continues to prioritize safety, reliability and sustainability, steel wheel weights remain an important option for ensuring a smooth and comfortable ride.

Post time: Nov-20-2023