TR413 Series Tubeless Valves Snap-in Tyre Valve & Chrome Sleeve Tire Valves

Product Description

-Maximum cold inflation pressure 65PSI.

-Maximum rim thickness of 4mm.

-Temperature range: -40°C to +100°C

-Components: Over molded rubber on brass stem, cap & seal, and core

|

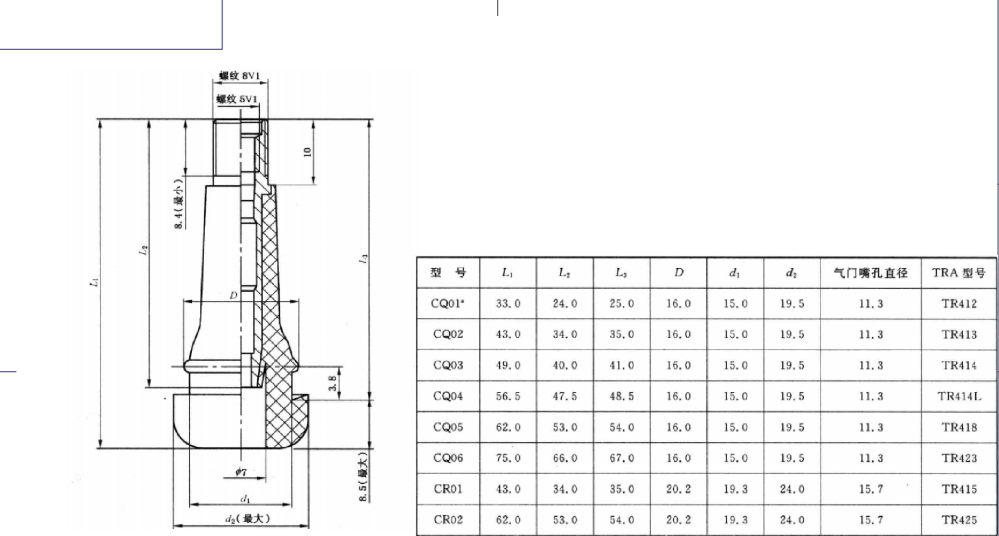

TRNO. |

Rim Hole |

Eff.length |

Parts |

A |

B |

C |

|

|

Core |

Cap |

||||||

|

TR412 |

Ф11.5/.453" |

22 |

9002# |

VC8 |

33 |

22 |

15 |

|

TR413 |

Ф11.5/.453" |

30 |

9002# |

VC8 |

42.5 |

32 |

15 |

|

TR414 |

Ф11.5/453" |

38 |

9002# |

VC8 |

48.5 |

38 |

15 |

|

TR414L |

Ф11.5/453" |

45 |

9002# |

VC8 |

56.5 |

46 |

15 |

|

TR418 |

Ф11.5/453" |

49 |

9002# |

VC8 |

61.5 |

51 |

15 |

|

TR423 |

Ф11.5/.453" |

62 |

9002# |

VC8 |

74 |

63.5 |

15 |

|

TR415 |

Ф16/ ,625" |

30 |

9002# |

VC8 |

42.5 |

32 |

19.2 |

|

TR425 |

Ф16/ .626" |

49 |

9002# |

VC8 |

61.5 |

51 |

19.2 |

|

TR438 |

Ф8.8/.346" |

32 |

9002# |

VC8 |

40.5 |

31 |

11 |

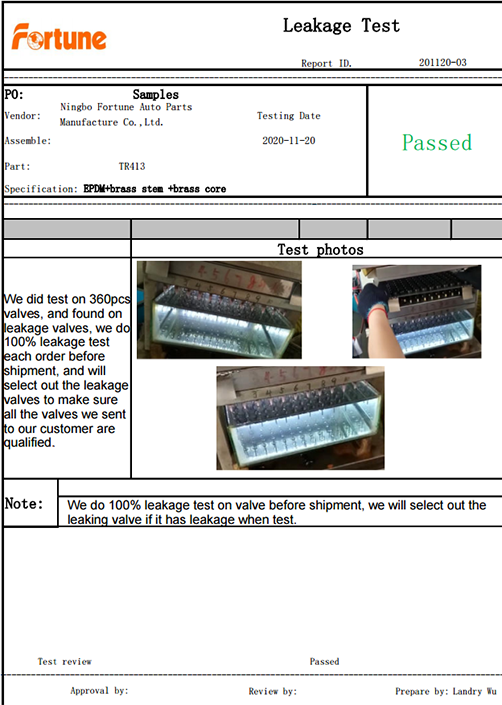

* All valves are 100% verified for air-tightness.

Have fulfilled the requirements for ISO/TS16949 certification by TUV management services.

Advantages

Though a tire valve stem is a small and inexpensive component in a tire &wheel assembly, it is very important and it relate directly to safe driving.

*All valves are 100% verified for air-tightness.

*Have fulfilled the requirements for ISO/TS16949 certification by TUV management services.

*We lay great stress on the quality of our valve stems. No any inferiors are allowed to be delivered to our customers.

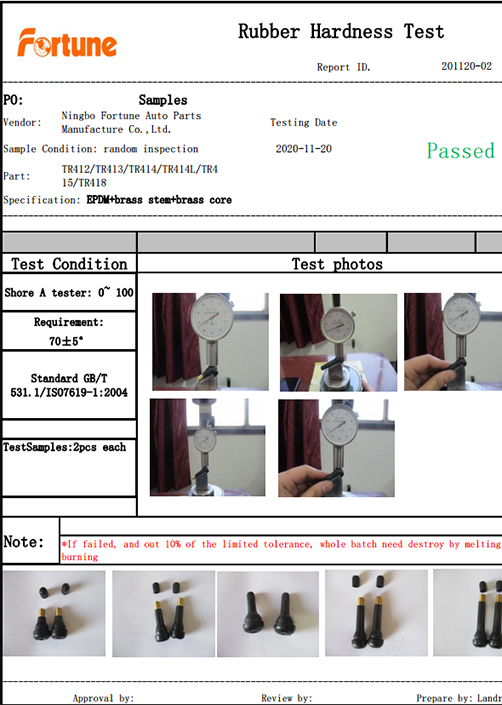

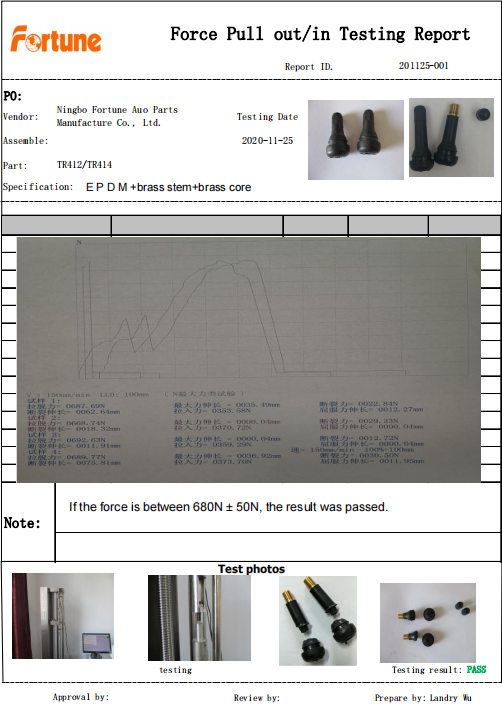

Strict Quality Control

To keep the good and steady quality, we adopt strict quality control system. All raw materials will be tested before used in production. Random inspection will be taken during the production processes. The tests include but are not limited to Rubber Hardness Test, Leakage Test, Ozone Resistance Test, Force Pull out/in Test, Adhesion &High Temperature Test. And before the shipment of an order, we do 100% leakage test and will select out the unqualified valves to make sure all the valves we sent to our customer are qualified.

Warm Notice

Due to the inevitable aging of the rubber material, the valve body will gradually crack, deform and lose its elasticity. When the vehicle is running, the rubber valve will also deform due to the centrifugal force swinging back and forth, which will further promote the aging of the rubber. Generally speaking, the life of the rubber valve is 3-4 years, which is similar to the life of the tire. Therefore, it is recommended to replace the rubber valve when replacing the tire.